Graduated rod for slice thickness adjustment

Painting without the use of transparent varnish as originally

← Scroll the images to view them →

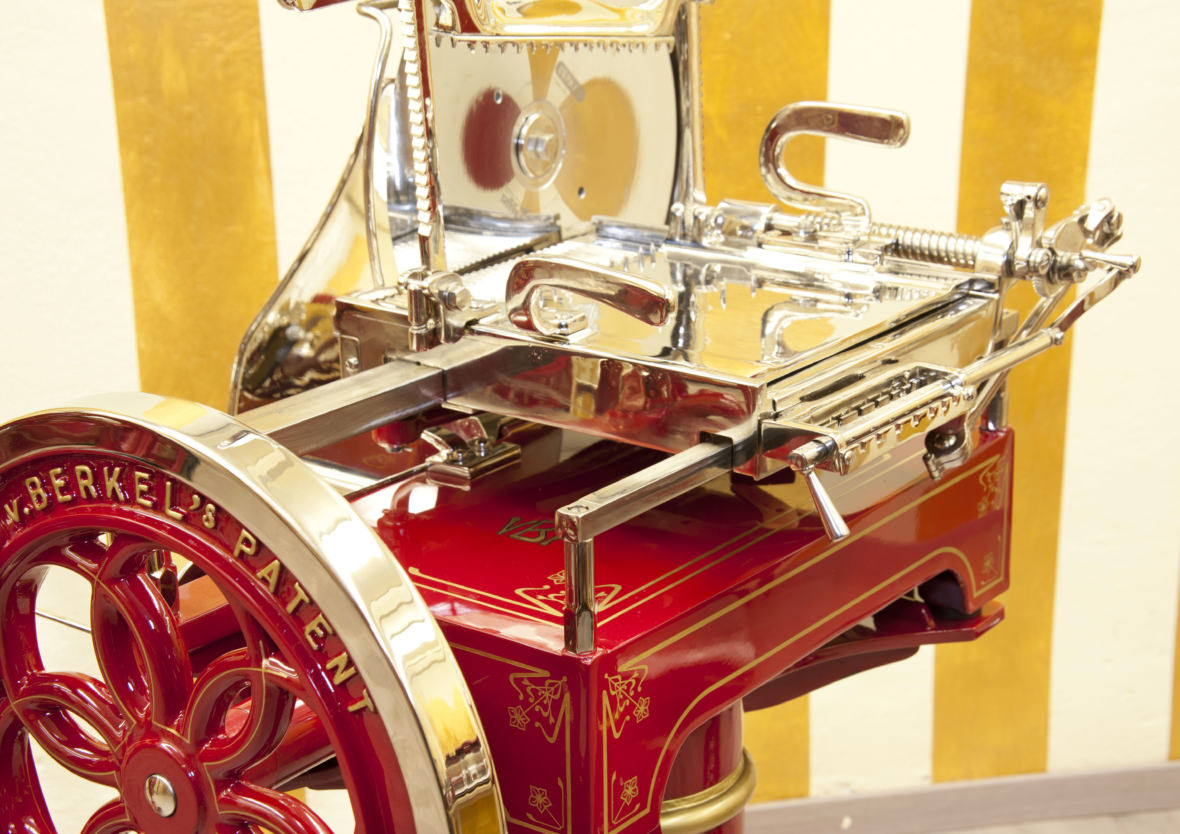

Berkel slicer model 1

Model: Berkel 1

Manufacturing time: 1908 – 1915

Place of origin: Netherlands – Rotterdam

Colour: Red

Slicing blade diameter: 350 mm

Weight: 94kg

Dimensions: width 58cm – depth 84cm – height 56cm

Note: Both vintage and replica pedestals are available

Berkel slicer model 1 is built contemporaneously with the models R – L – 2.

Together with the models 2 – R, it is the most innovative one of that time with a really revolutionary mechanism; for this reason it is the most appreciated and wanted one among the rare models.

On the other hand, the model L uses the mechanism of its previous models C – D that is more “Spartan” and simple.

The machine has a flower shaped flywheel putting a gearing into action located under the base. It drives both the blade by means of a chain and the cart by means of two connecting rods.

The cart, in side near the blade, shifts through a big sized rectangular rod. It is slotted with adjustable guides.

On the contrary, at the opposite side, the cart leans on a smaller square rod and shifts thanks to a felt.

Those two rods are supported by four small columns fixed on the base, two for each guide.

The connecting rod, giving the motion to the cart, is synchronized with a cam lever standing under the cart.

Everything is connected to a cog-wheel through a rod giving the movement to the endless screw, where the vice comb, giving the slice thickness, is fitted.

The cog-wheel is joined to a cam-plate driven by graduated rod located on the cart setting out the slice thickness. It is connected to a crank that, when moved on the right or left, shifts the vice consequently, as you whish.

So these synchronisms carry out the cut of the product to be sliced by the only movement of the shifting cart; without the help of any other mechanisms placed on the slicer base.

The vice, fixing the product to be sliced, consists of two opposite rack rods, connected by a toothed arm acting on the product to be sliced and is inserted with a slot on the shifting cart.

The shoulder has the classic round and closed shape. There are fixed on it: the hub supporting the blade, the plated tray where the slices drop, the front and the back blade protectors, the label of the Barkel brand located on the plate bottom.

The sharpener is nickeled and consists of more pieces on view, without any fairings.

The manifesto of our Berkel restoration

We do ensure maximum fidelity to the historical period of reference: here’s why we apply the oven painting without the use of transparent paint, as originally done in all Berkel models.We use the original copal paint brands of the time.

In the same philosophy we carry out decorations by hand without the use of an airbrush and issue the “Certificate of Authenticity”, guaranteeing excellent operation for 5 years after delivery.

For further information please read the page “Art of Restoration”.

For information about the machines on sale, please send us an email at .